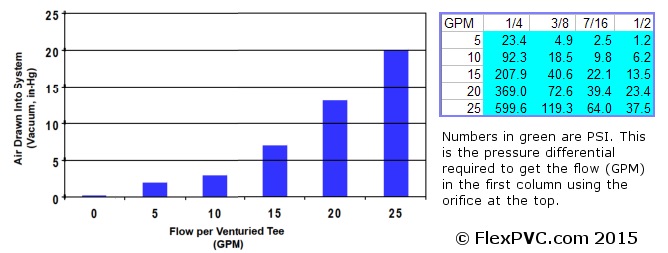

Note: The numbers in green are the pressure differential needed to achieve the vacuum in the vacuum port of the Venturi tee fittings. The pressure differential is the difference in pressure between the input and output of the PVC Venturi tees.

As an example suppose you had a tank 10' tall with 10' of water column in it. 10' of water column converts to about 4.5psi. Now lets say you want your Venturi to pull 15inHg of vacuum. What that means is you need 22 or 23 GPM thru the Venturi. So you look in the chart on the right and you will see 20 and 25GPM. Now you decide to run a 3/8" nozzle in the Venturi. You can see you need between 72.6psi (at 20GPM) and 119.3psi (at 25GPM) so you can extrapolate you will need about 96psi ((72.6+119.3)/2). However the tank water column has about 4.5psi on the output of the Venturi. You will need about 100psi at the input of the Venturi tee fitting (96+4.5). So you will have to have a pump that will provide about 100psi thru a 3/8" opening. Or if you wanted to use a 1/4" orifice you need a pump that could put out about 485psi. ((369+599)/2+4.5)). Or if you used a 1/2" orifice (you'd have to drill out the 7/16th orifice to do this) you could use a pump with 36psi ((23.4+37.5)/2+4.5).

If you wanted a different vacuum you'd have to redo the whole calculation. So you can see it's easier to use a larger orifice. If you are using several PVC Venturi tees off one pump, you can run out of pump very quickly. For example, it's easy to find a pump that will do 36psi at 25GPM, but if you had 5 Venturi tee fittings that be 36psi at 125GPM, which would be about a 3-5hp pump!

This is where the Pump Flow Chart comes in handy. Most of the pumps we sell have a flow chart that shows pressure (PSI) as a function of flow (GPM). You will need to calculate what vacuum you want and the number of PVC Venturi tees you want and then find a pump that will provide the pressure and volume needed.